Oerlikon Spunbond Meltblown Complete Line

Type: Meltblown line Width: 1700mm YOC: 2020 EL: 380/3/50

Complete meltblown line consisting of:

*Raw material supply

– Raw material storage system – 1 silo, approx. 150 t capacity

– Central chips conveying system, max. conveying length: 12 m vertical / 18 m horizontal

– Metering and mixing system, type: gravimetric / batch wise, components: 1 main + 3 additives, min. dosing amount for additives: 250 g/h, with 1 operating panel

*Set of extrusion and spinning equipment

– Extruder system, throughput range: 40 – 150 kg/h PP (MFI 400 – 1.200), screw size: ø90 mm, cylinder heating: 5 zones / 58 kW, polymer temperature and pressure measurement

– Polymer filter, bolt filter system, screen area: 2 x 72 cm², operation mode: continuous, semi-automatic

– Polymer distribution pipeline, electrically heated, all parts coming into contact with the product are made out of stainless steel

*Meltblown spinning beam consisting of:

– electrically heated meltblown die assembly, max. operating temperature (design): up to 300°C, heating power (total): up to 52 kW, die body (coat hanger), heaters plus temperature sensors for individual control loops, melt pressure and temperature sensors, air manifold (segmented): double-sided for heated process air, pressure measuring devices, spinning pump: 1 x 70 cm³/revolutions incl. drive system

– 2 spin packs (one in operation and one in stand-by), for PP polymer, hole to hole width: 1.700 mm, holes per inch: 50 hpi with quick change feature

– Double-sided quench box

– Quench duct

– Steel frame. The structure is laid out to accommodate extruder, polymer filter, spinning beam and manifold, quench boxes.

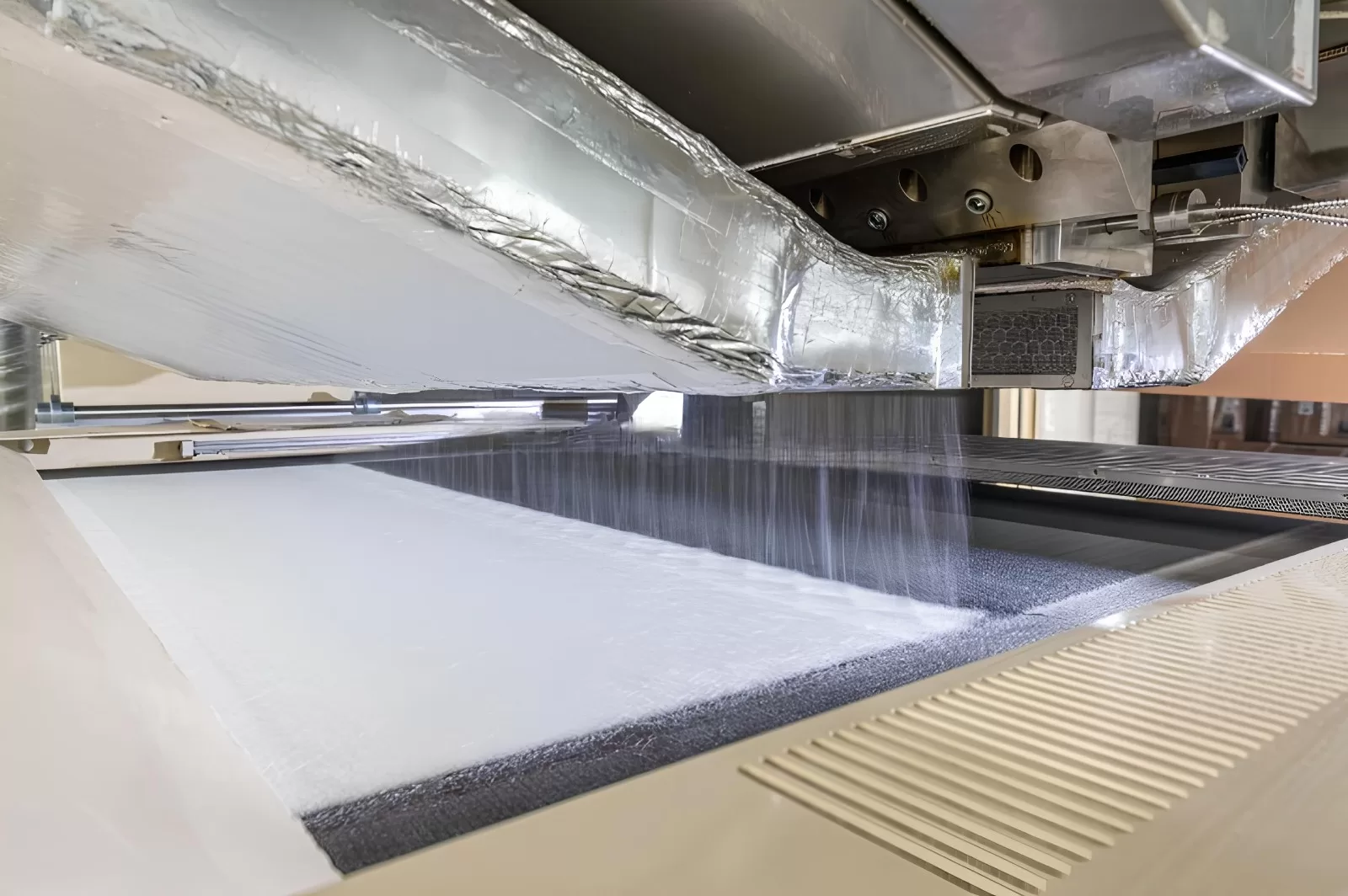

*Web Forming System

– Fabric forming table, multifunctional forming table, suction width: 1.850 mm, speed range: 4 – 80 m/min, forming wire with pin-seam, height adjustment via motor driven spindle system adjustable DCD: 150 – 600 mm, set of rollers for forming wire support, 3-zone vacuum box with upstream zone, forming zone and downstream zone, pedestal staircase, guiding system for forming wire, tensioning system for forming wire, forming wire drive system

– Air suction systems, the suction system for forming air consisting of channels between vacuum box and fan

*Air Suction Fans

– Set of meltblown air suction fans, with drives and controls, 1 fan for upstream zone, 1 fan for forming zone, 1 fan for downstream zone

*Quench Air System

– Secondary air system for quench air consisting of: air inlet zone with filter, air cooling zone (by chilled water) incl. condensate return, air heating zone (by the electric heater), air pressure blower zone, quench air temperature: 15 – 40 °C

*Chilled Water Unit

– chilled water circulation system piping and pumps, galvanised steel chilled water tank, insulation for chilled water circulation system, circulating system for extruder cooling

*Process Air System

– Process air compressor, air volume per beam: approx. 900 – 3.000 Nm³/h, Pressure: 0,1 – 1,5 bar (g), sound enclosure, pressure and temperature sensor (analog output), electronic control unit, drives, air piping and bypass valve between compressor station, air heater and air manifold, insulation piping

*Air Heater system

– Electrically heated air heater, pressure: 2 bar (g), the temperature at the exit side of heater: 160 – 350 °C

*Electric Charge System

– Oerlikon Neumag – ecuTEC 1600 electrostatic charging unit, multifunctional for in-line charging of the web, needle electrodes (Tech-I), side frame, set of high voltage generators, safety covering

*Winding System

– Mahlo online basis-weight and air-permeability measuring system

– A. Celli in-line slitting winder, contact winder with coated drive drum, operation speed range 4 – 90 m/min, web width 1.600 – 2.200 mm, max. roll Ø 1.200 mm, max roll weight 630 kg, 4 winding shaft – dia 3 inch, 12 slitting knives (including edge trim) position manually adjustable. Consisting of: web threading by means of threading belt and air blowers, load cells for automatic tension control, bowed spreader roll, spool storage station, spool start-up system, two primary arms to transfer the spool from the loading position to the horizontal tracks, arms – supporting the spool during winding actuated by pneumatic cylinders, slitting section, driven by an independent motor, reel sustaining device, automatic roll doffing and cross cutting unit (with rotary blade), nip control, taper function, operator panel, crane without columns connected to the meltblown steel frame, simple V-shaped unloading table to receive the finished reel unloading table, shaft extractor system, crane yoke for its transfer back to the spool storage station, edge-trim suction, suitable for meltblown filter material 15 – 80 gsm, max trim width: 50 mm

*Electrical system

– Siemens PLC and process control system, local operating panels, measuring sensors, safety limit switches, heating switch cabinets, drive switch cabinets incl. inverters, switch cabinets for auxiliary devices, measuring and control panel, emergency stop / fast stop devices

*Auxiliaries

– Set of special tools for the extrusion equipment

– Spinneret workshop consisting of preheating oven, ultrasonic bath, spinneret microscope, vacuum pyrolysis oven, lifting pulley for spin pack handling, assembly table for mounting the spin pack